Strong Plywood Box for a Holding Tank

/An aluminum holding tank would have been so easy to install here. They come with mounting tabs welded on, through bolt them to a bulkhead and you're done. Until the bottom drops out because aluminum is a terrible holding tank material.

A rotomolded polyethylene tank doesn't have any features to help with mounting so it needs a lot of help. This is a Okoume ply cabinet that is through bolted to a bulkhead and is screwed to a double thickness cleat that is fitted and tabbed into the hull. The corner of the cabinet is so solid it can be used as a step to get out of the locker. The hull tabbing might seem to be overkill but the tank would weigh over 115 lbs full and I don't want it to move.

The tank barely fit and the cabinet didn't fit at all. It was mostly assembled in the locker, in my lap, with stainless brads and Titebond III glue. This was not fun.

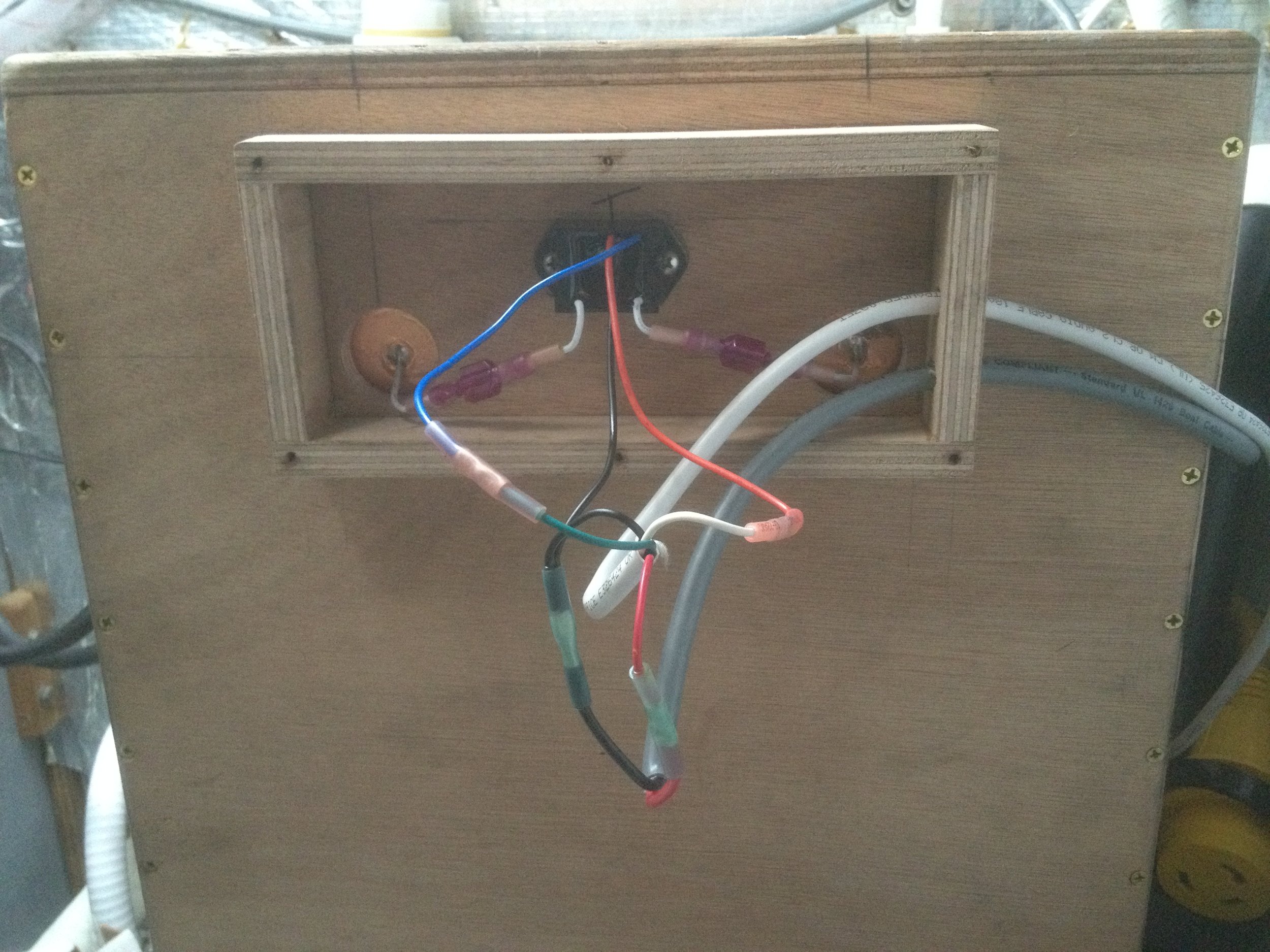

A SCAD tank monitoring system was installed and a wooden junction box was built to hold the wiring.

A big improvement would be a plastic standpipe that enters from the top deck of the tank for pumpout instead of the fitting at the bottom of the tank. The pumpout hose is constantly wet up to the tank level, a recipe for permeating. It's a short length and easy to replace but it would last much longer with this change. I also would have gone from the typical 1/2" ID vent hose fitting to 3/4" or larger, more airflow only helps.